A regular enquiry received by HERA has been the application of fatigue design in steel bridges. On one hand, some designers have had trouble interpreting the current design rules; whilst on the other, many fabricators have expressed concerns on more expensive butt welds being specified for fatigue details where this might not be entirely necessary.

In response, a joint research project between the HERA Welding Centre, Structural Systems division, University of Applied Sciences, Wilhelmshaven, Germany and University of New South Wales, Australia has been undertaken.

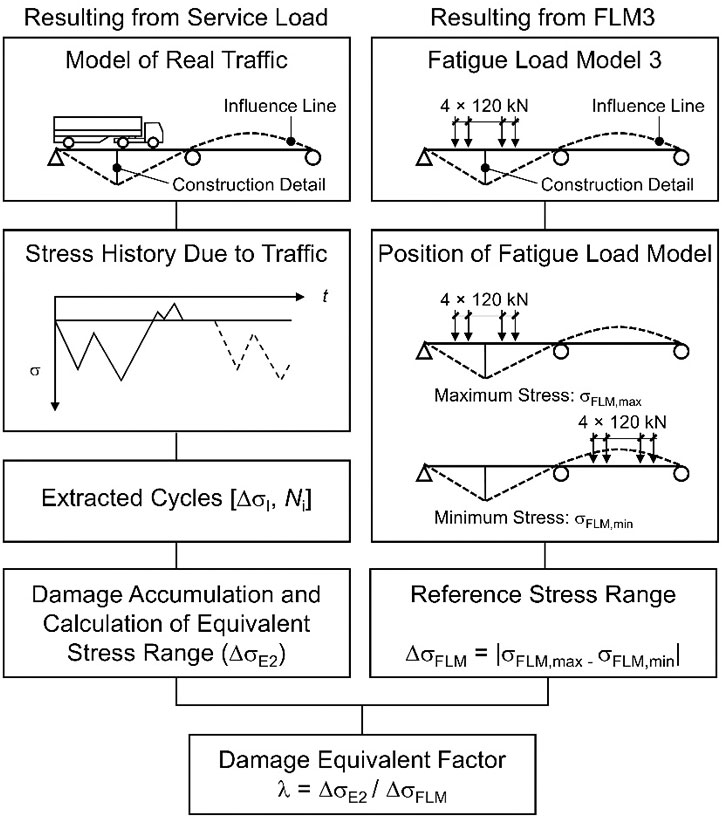

This research project considered implementing the Eurocode damage equivalent factor format into the forthcoming steel and composite bridge standard AS/NZS 5100.6, by considering the existing fatigue loading given in AS 5100.2. The benefit of implementing this format is that it greatly simplifies the fatigue calculations that are required by the engineer and provides more transparency together with flexibility within the design process.

Through working closely with the lead author of the IIW fatigue publication, Prof. Adolf Hobbacher, as well as implementing the damage equivalent factor format, the latest thinking from IIW has also been incorporated within the AS/NZS 5100.6 provisions, which includes the fabrication requirements needed to achieve a particular detail category.

The concept of reliability differentiation given in ISO 2394 is also introduced through the ‘damage tolerant method’; and the ‘safe life method’. The damage tolerant method provides acceptable reliability that a structure will perform satisfactorily for its design life with an inspection and maintenance regime for detecting and correcting fatigue damage and, due to this extra maintenance effort, permits lower capacity reduction factors to be used in design.

Conversely, for the safe life method, an acceptable reliability is provided without need for regular service inspections; however a larger capacity reduction factor is required in design. A paper on the background to the proposed fatigue provisions in AS/NZS 5100.6 has recently been published in the international peer-reviewed Journal of Constructional Steel Research.

Further information, contact our General Manager Structural Systems Dr Stephen Hicks. The new fatigue design concept of AS/NZS 5100.6 will be explained in seminars with Prof Adolf Hobbacher.

The venues are:

- Hamilton 22 July

- Auckland 25 July

- Wellington 28 July

- Christchurch 2 August

- Queenstown 5 August