Reinforced concrete structures often use the “seismic” grade of reinforcing bar 500E (to AS/NZS 4671).

The designation “500E” means the reinforcing rebar must meet specific requirements in regards to mechanical properties to ensure the bar will have adequate performance under earthquake loading.

The yield strength must be between 500 – 600MPa, the minimum elongation is to be 10%, and the yield-to-tensile strength ratio 1.15. The yield-to-tensile ratio of a material indicates the ability of a rebar to experience plastic deformation before failure.

The 500E grade reinforcing bar

Described as a high tensile, high ductility plain carbon (micro-alloyed) steel. It is readily welded provided appropriate welding procedures are followed. AS/NZS 1554 Part 3 Welding of reinforcing steel is the most widely specified welding standard for rebar in NZ. This standard sets out the requirements for the qualification of welding procedure for most of the joints commonly encountered including butt joints, lap joints, and for end plates.

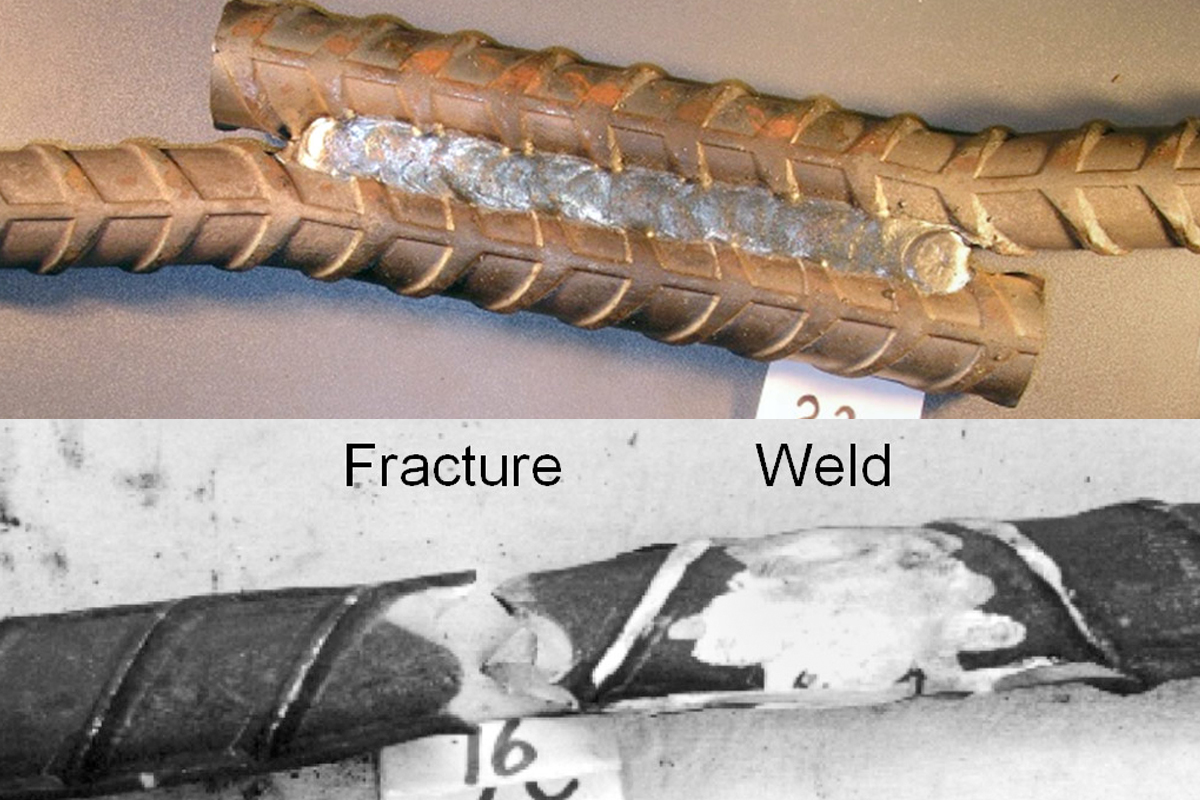

Unfortunately, not all welders are aware of the influence of the joint design has on the performance of the connection under earthquake loads; the joint is only considered in terms of simple static loading. Often rebar welds need to be made on site because of mistakes made by contractors who expertise is in concrete construction; not welding.

Welders must be made aware that the designer may have specific requirements for joins in rebar.

For example a double-lap splice joint (two bars positioned side-by-side) will not perform the same as a direct butt splice joint.

Grade 500E rebar may have a carbon equivalent (CE) up to 0.49% which is relatively high compared to the materials that covered by AS/NZS 1554.1. Higher CEs require careful consideration for preheat however for 500E rebar preheat is not required in most situations provided hydrogen controlled welding procedures are used. This is because the combined thickness of joints between round bars results in a slower cooling rate than for the same thickness of joints between plates.

For lap joints the “prequalified” method of procedure qualification allows some choice in the welding consumable used; consumables that under match the mechanical properties of the bar are permitted provided weld size and lengths are in accordance with the Standard. However for direct butt splice welds there are no consumables deemed prequalified and so the only option is qualification by testing.

AS/NZS 1554 Part 3 Welding of reinforcing steel is in the process of being amended to ensure its technical accuracy and will be available for public comments. The draft standard will be available for public comments on Standards NZ webpage soon.

Get your skills up to date today!

For those whose responsibilities include the supervision or inspection of the welding of rebar the HERA Welding Inspection Part 1/Welding Supervisor course provides the knowledge required to ensure rebar is welded correctly. Click here for more course details

Update shared by General Manager Welding Centre Michail Karpenko