Corrosion often occurs in well-hidden, difficult to access locations in steel structures, where water and debris accumulate over time. Regular inspections might overlook these areas and sometimes they are only discovered when severe loss of cross section has already occurred. This is the time when structural engineers face the challenge of assessing the remaining capacity of the steel members/plates/connections and must decide what can be done.

Advanced numerical tools allow the accurate mapping of in-situ corrosion (i.e., modelling corroded plates with varying thicknesses as measured), calculate the forces transferred through the structural steel and to predict the ultimate limit state (ULS). It is also possible to add welds and/or other plates/cleats/fasteners to an already stressed structure and to calculate the response (stress, strain, deformation, and others) of the strengthened structure, evaluating the benefits of different options.

Initial imperfections can also be included in the non-linear static or dynamic simulations.

HERA used Abaqus finite element software to assist a member company in this respect recently.

Assessing and extending the life of existing structures with such an issue saves resources in many fronts (costs, interruptions, sustainability, etc.).

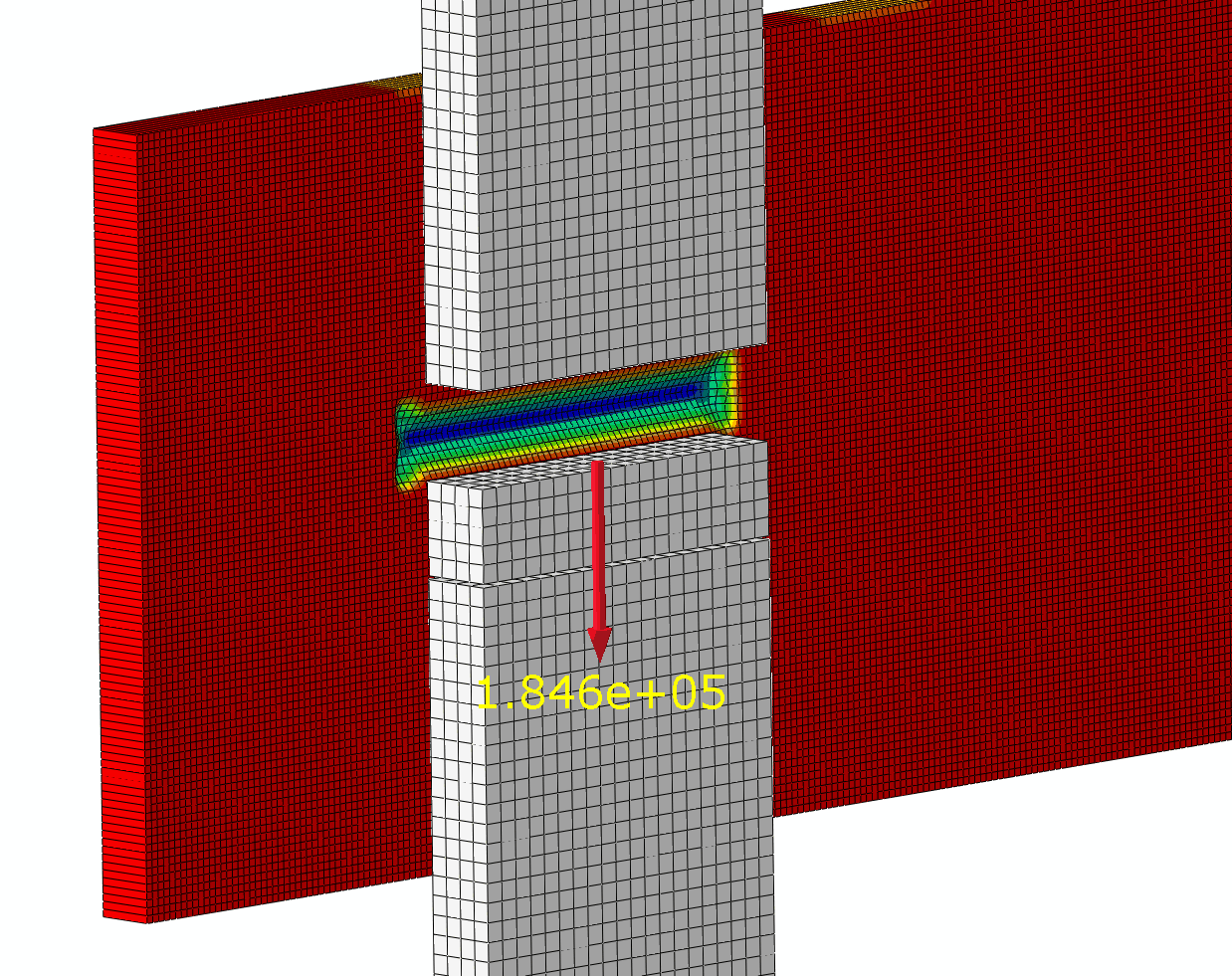

An illustrative example of a corroded plate and added repair weld is shown below. Only the bottom half of the repair weld and the resultant force transferred through the weld is shown for clarity.