A recent technical study has come to HERA’s attention as it highlights our stance that you should choose infrastructure material based on design parameters.

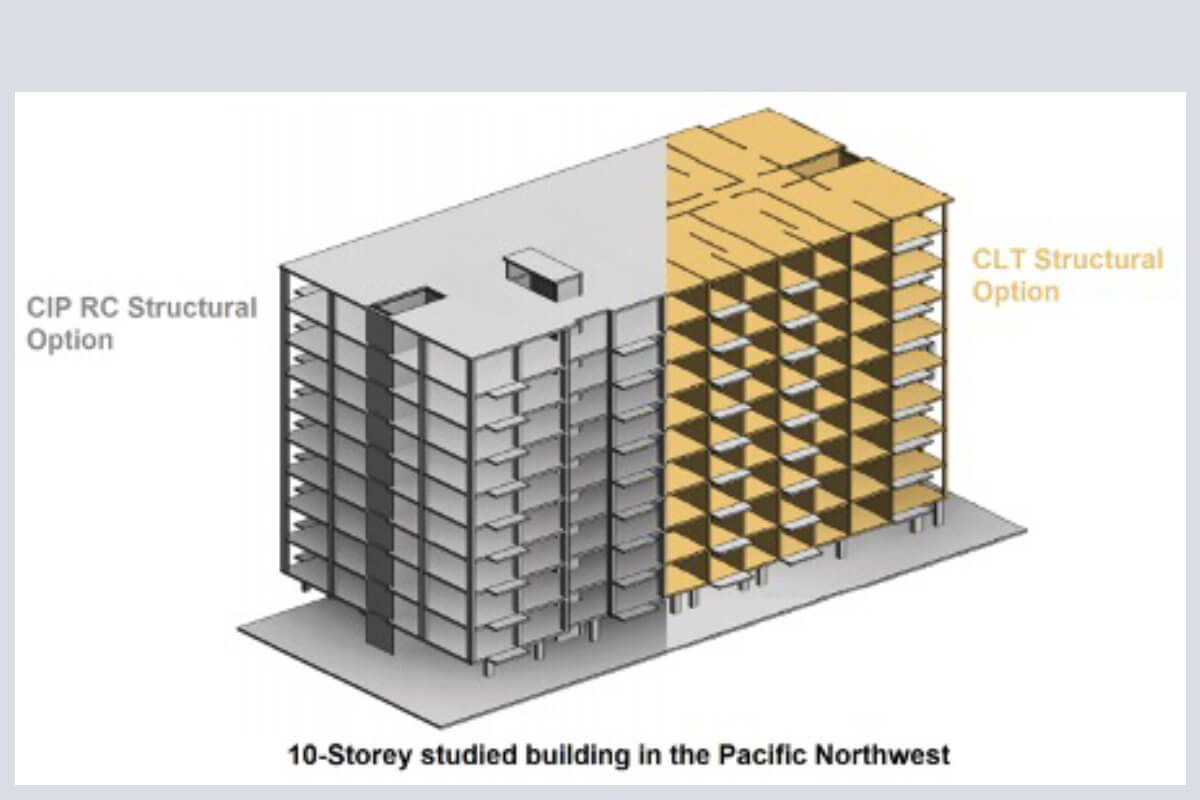

The technical study that we refer to was performed by the structural engineering firm Cary Kopczynski & Company in Seattle, WA. It compared the affordability of a hypothetical 10-story residential building located in the US using cross laminated timber (CLT) and cast-in-place reinforced concrete (CIP RC).

A layout representative of an urban mid-rise multifamily residential building was used to develop the structural design for both options considered. HERA notes that the study has limitations in terms of available data and the fact that pricing varies by region. Hence, this study in no way represents consistent relative performance.

About the study

The International Building Code (IBC 2015 edition) and the 2010 edition of Minimum Design Loads for Buildings and Other Structures (ASCE/SEI 7-10) were used to determine design loads. The latest Material Design Standards were used to design the building for both strength and serviceability. Wind loadings governed the design of the building.

Both CLT and CIP RC structural options meet constructability requirements of a hypothetical 10-story multifamily residential structure in the United States.

The two design options were:

- Cross Laminated Timber: the 150mm thick, 5 – lam CLT wall panels were used to support the gravity and lateral design loads. CLT floor panels of the same thickness were used. It was noted that spans selected for the CLT option were shorter in some areas than those for the concrete option due to the vibration potential for CLT floor systems with longer spans. 245mm thick, 7 – lam CLT floor panels were used at corners where floor span exceeded 4.9m.

- Cast-in-place Reinforced Concrete: comprising a flat plate system with gravity columns and 300mm thick concrete shear walls. Slabs were 230mm thick normal weight concrete reinforced with mild-steel reinforcement. The compression strength of the concrete (f’c) for slab was 35MPa and for columns and walls was 40MPa.

The key findings of the study were:

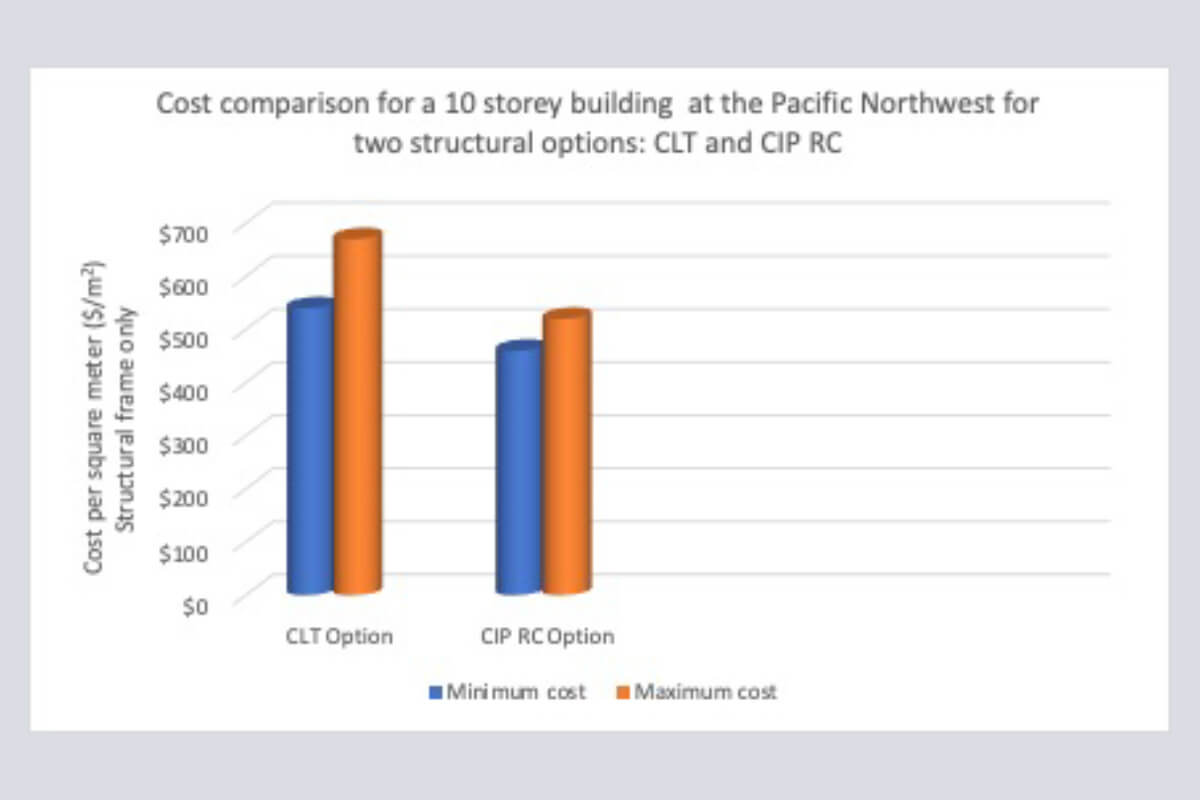

Economy: the cost of a CLT structural frame is 16% to 29% higher than a competing cast-in-place concrete structure.

In Pacific Northwest, the cost of a CLT structural frame is 16% to 29% higher than a competing cast-in-place concrete structure. The margin will vary, depending on geographic region. Cost of CLT would increase further in the North America out of Pacific Northwest. Figure 1 compares the minimum and maximum cost of the of CLT and CIP RC structural options of the 10-storey building in the Pacific Northwest.

In the high seismic regions, CLT may not be appropriate

While both CLT and CIP RC were suitable for lateral resisting systems of the multi-storey building in the regions where wind governs the design, in high seismic regions the pure CLT cannot be used.

Moreover, floor vibration under dynamic load, excessive lateral drift under wind or seismic loads and fire performance and life safety are among challenges and knowledge gaps that need to be addressed when using CLT system in multi-storey buildings.

Whole of life carbon assessment is important

The study noted that “the choice of structural material has limited impact on the total energy consumed over a building’s life, since the structure affects only Embodied Energy – the energy required to produce the building’s physical materials. Operational Energy – the energy required to heat, cool, light, and operate a building – is dominant, being upwards of 95% of the total energy consumed.”

What is HERA’s stance on this?

In Aotearoa, the Building for Climate Change program is requiring carbon reductions in new builds. To meet this challenge, the full environmental impacts of the buildings during their lifetime (i.e.not just embodied carbon) must be evaluated. Re-use is a zero carbon strategy beyond materials manufacturing.

At HERA, we do not support any claims that one material is holus bolus superior to the other, because it all depends on what the specific conditions are and what the design entails. We support choosing the right material for the right design.

We also refute the widely misheld assumption that CLT is the preferred sustainable (and affordable) choice. The evidence simply does not support such blanket statements. Further, the findings of this study put into question its suitability in seismic environments and further research should be conducted to confirm its suitability for Aotearoa New Zealand.