HERA has successfully provided Advanced FEA services to a range of projects both in Aotearoa and abroad.

FEA is one of the most powerful numerical methods available to solve partial differential equations for complex structures. Providing a direct pathway to understand the feasibility of a new design or troubleshoot a problem. All without the need to prototype and waste time and money.

It is why we’re proud to have our Finite Element Analyst, Nandor Mago on our team, so we can extend this expertise to industry and ensure that they’re making informed decisions for their project.

His focus being to leverage advanced finite element analysis (FEA) to accurately predict the behaviour of your building – so you can make the right decisions early.

Case study 1 – 75% saving of passive fire protection on long-span secondary beams

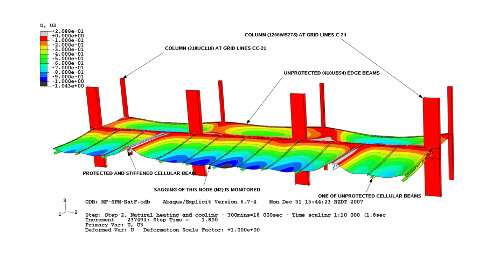

We were engaged to assess the structural response of a composite steel-concrete structure that was part of the Britomart East office building in the Auckland CBD. Within this package of work, evaluating a range of fire severities.

Advanced FEA formed an integral part of the Slab Panel Method fire engineering design procedure used in the design.

From our analyses it was demonstrated that the passive fire protection could be eliminated from the long-span secondary beams, with only elements critical to the structural stability of the floor requiring the application of fire proofing materials.

The 75% reduction to the passive fire protection on the long-span cellular beams resulting in significant cost savings to the client.

Case study 2 – Optimisation of joints at preliminary design stage

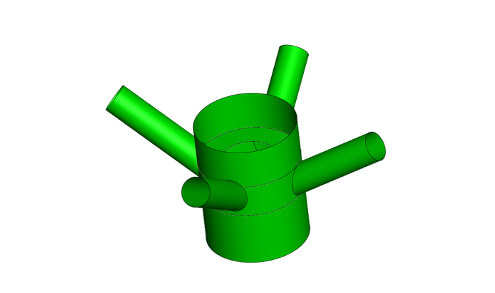

Although the initial design of a column tree head to the roof of the Newmarket train station was sound from a structural point of view, a significant amount of welding was required which would mean substantial welding-induced distortions.

As a result, new stiffening details to the column head were proposed to the client and verified through FEA.

A move that significantly reduced the fabrication cost to the column tree head.

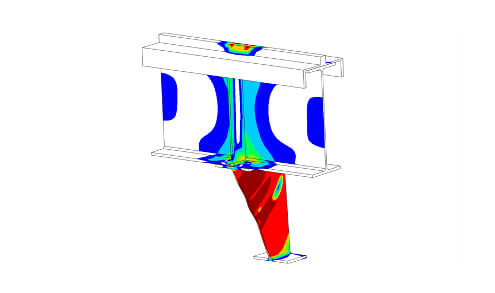

Case study 3 – Assessment of structures not supported by existing design standards

Because the NZS3404 provisions didn’t properly cover the corbel to the crane-beam, we assessed the structural performance of the detail using finite element analyses.

Initially a ‘perfect’ model, which was based on nominal dimensions and material strengths, was constructed and analysed.

Following the completion of this, the model was then made ‘imperfect’ by considering the maximum dimensional tolerances that are permitted by the current Codes of Practice.

By comparing the results from a non-linear analysis of the two models, we were then able to evaluate the maximum crane wheel load that could safely be applied to the structure.

Case study 4 – Assessment of factors leading to structural failure

In this project, the aluminium culvert collapsed shortly after installation due to buckling failure.

We assisted the client to understand what led to the collapse by conducting a thorough FEA investigation.

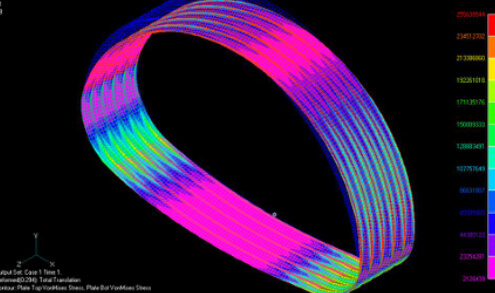

Case study 5 – Product development and assessment of the fatigue strength of structures and components

The aim of this project was to reduce the stresses in the critical regions of the equipment attachment when crushing rocks.

Our finite element model was able to achieve this, by identifying areas of concern. A step that increased its fatigue life for our clients product.