The fire design of steel-concrete composite columns using concrete filled tubes to EN 1994-1-2:2005+A1:2014 (Eurocode 4) is seemingly a simple task, assuming that the temperature distribution of the cross-section is conservatively known.

Reading the rules in the section that deals with the structural behaviour and evaluation of the resistance to axial compression, one gets the impression that there are unified rules which cover all types of columns.

In reality, all ends to confusion and limitations once we take into account the field of applications as described in Annex H of Eurocode 4.

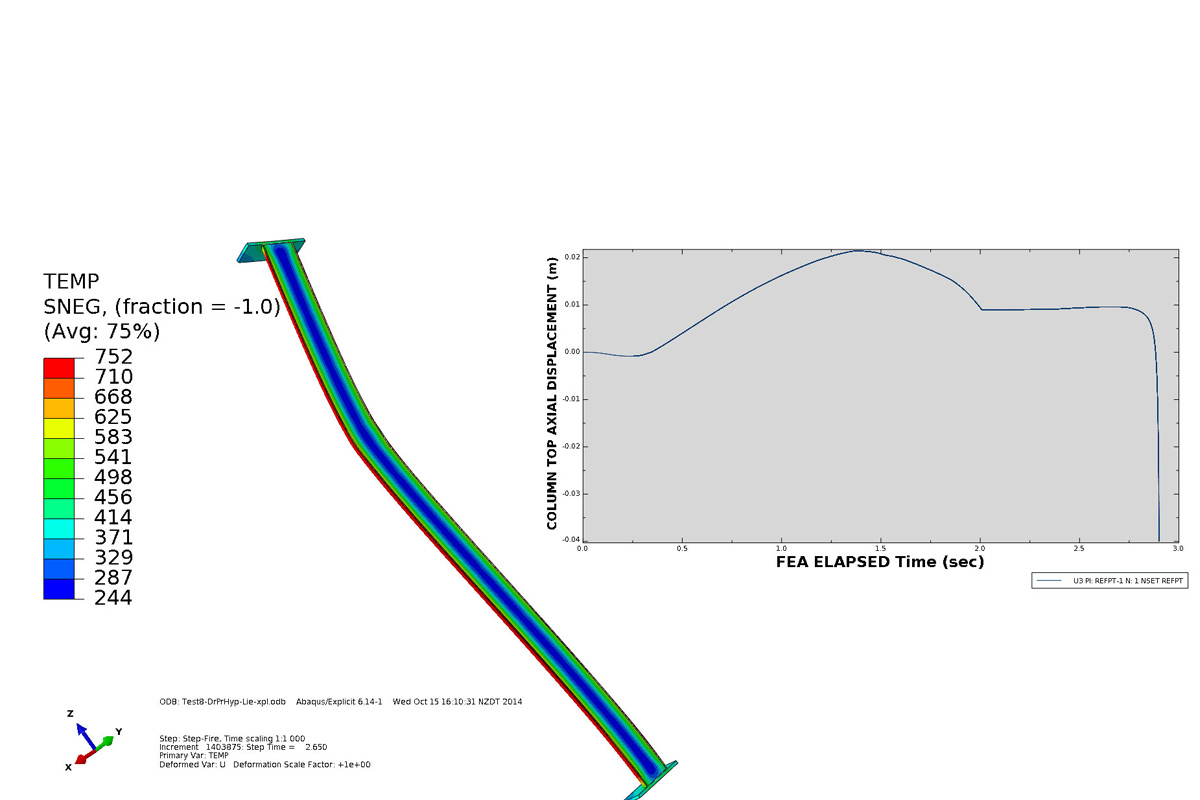

Based on HERA’s extensive background in experimental and numerical fire research, a sequentially coupled thermal-stress analysis procedure has been developed and validated against international fire test results published by CIDECT, which can be applied to any column. The procedure has been successfully used on steel-concrete composite slabs and columns, but in general it can be applied to any structural member.

Currently, version 6.14 of Abaqus state of the art finite element software (http://www.3ds.com/products-services/simulia/portfolio/abaqus/latest-release/ ) is in use to further enhance the numerical simulations, which predict the composite column fire resistance rating (FRR) expressed in minutes.

The realistic simulations can take into account the concrete type (siliceous or carbonate), strength (normal or high strength concrete), initial column geometric imperfections, thermal and mechanical contact between the steel and concrete, amount of reinforcement, etc.

A variety of fire loading scenarios can be simulated too. In other words, it is not just the standard ISO 834 fire (heating) curve but natural fire conditions, including the cooling down period.

The fire resistance of concrete filled hollow steel structural columns filled with carbonate aggregate concrete is typically about 10% higher than siliceous aggregate concrete-filled columns.

Abaqus is used by designers, engineers and researchers in a broad range of industries, including electronics, consumer packaged goods, aerospace, automotive, energy, and life sciences to evaluate real-world behaviour of materials, products and manufacturing processes.

Both the implicit (Abaqus/Standard) and explicit (Abaqus/Explicit) solvers are in frequent use at HERA to solve a variety of engineering problems.

For those who are less involved in Finite Element Analysis (FEA for short), it is to be noted that the implicit solver is used for general engineering problems in which there is a static equilibrium.

The explicit solver had been developed to solve high strain rate problems (impact, car crash, some metal forming problems, etc) in which the dynamic equilibrium governs.

There is an overlapping region of quasi-static engineering problems, which can be solved with either solver, but the suitability / effectiveness should be assessed on a case-by-case basis. Fire is a typical case of a quasi-static extreme event.

Reference

[1] Manuel L. Romero, V. Moliner, A. Espinos, C. Ibañez, A. Hospitaler: Fire behavior of axially loaded slender high strength concrete-filled tubular columns, Journal of Constructional Steel Research 67 (2011)

Update shared by our General Manager Structural Systems Dr Stephen Hicks