Auckland University of Technology School of Engineering

This year, Auckland University of Technology’s School of Engineering students displayed their final year projects. HERA has traditionally given a prize for the best project involving metals. This year’s HERA prize winners was Mr Karl Waters, BE (Mechanical) with his project entitled Vertical Axis Wind Turbine Trade Studies.

The project undertaken sought to understand how vertical axis wind turbines function and develop an understanding for how variations in their geometry facilitated maximised performance with respect to the Betz limit for double actuator discs.

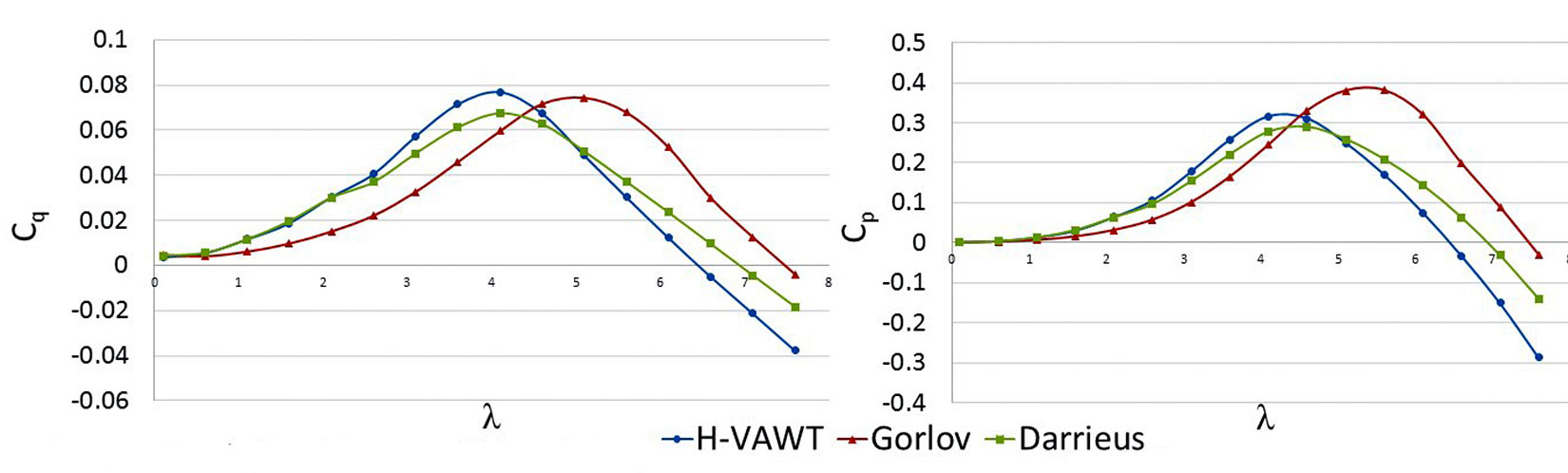

Three lift-driven vertical axis wind turbine variants were studied – namely the straight bladed and troposkein curved Darrieus rotors, as well as the helical Gorlov rotor.

The project accomplished the objective via a series of trade-studies undertaken in a software-based simulation environment – in which four series of studies were undertaken.

Firstly, a general performance comparison between the turbines, which revealed a significant peak performance advantage of the Gorlov. Secondly, an inter-rotor trade-study was undertaken in which simulations of design parameter changes were made to understand their influence on rotor performance, followed by a series of in-depth simulations examining the normal and thrust forces, angle of attack and induced velocity acting on the rotor blades.

Finally, the project undertook refinement of the Gorlov rotor for which a series of analyses was undertaken at 0.25 increments of tip speed ratio. The analyses developed an insight into the role that various aerodynamic phenomena had on the overall performance of a vertical axis wind turbine.

In conclusion, a Gorlov rotor with a peak performance of 59.8% was attained, which embodied a helical leading edge, fixed nose-out pitch and low solidity.

The simulations additionally found that the presence of dynamic stall was the limiting factor for the rotor at low tip speeds, and low angles of attack the contributing limiting factor at high tip speeds – demonstrating the changing flow conditions experienced by a vertical axis wind turbine through its full operating tip speed range. The project’s undertaking developed a body of knowledge with regard to vertical axis wind turbine functionality and performance.

HERA congratulates Karl Waters on his award and wishes him all the best with his career in engineering.

Auckland University Department of Mechanical Engineering

Every year, Auckland University’s Department of Mechanical Engineering was displaying their final year student projects. HERA traditionally contributes a prize for the best project involving metals.

This year’s HERA prize winners were Mr Haoda Yang and Mr Jose Gabriel Cachero with their project entitled New Zealand Steel Production Optimisation through Reduction in Transitional Downtime.

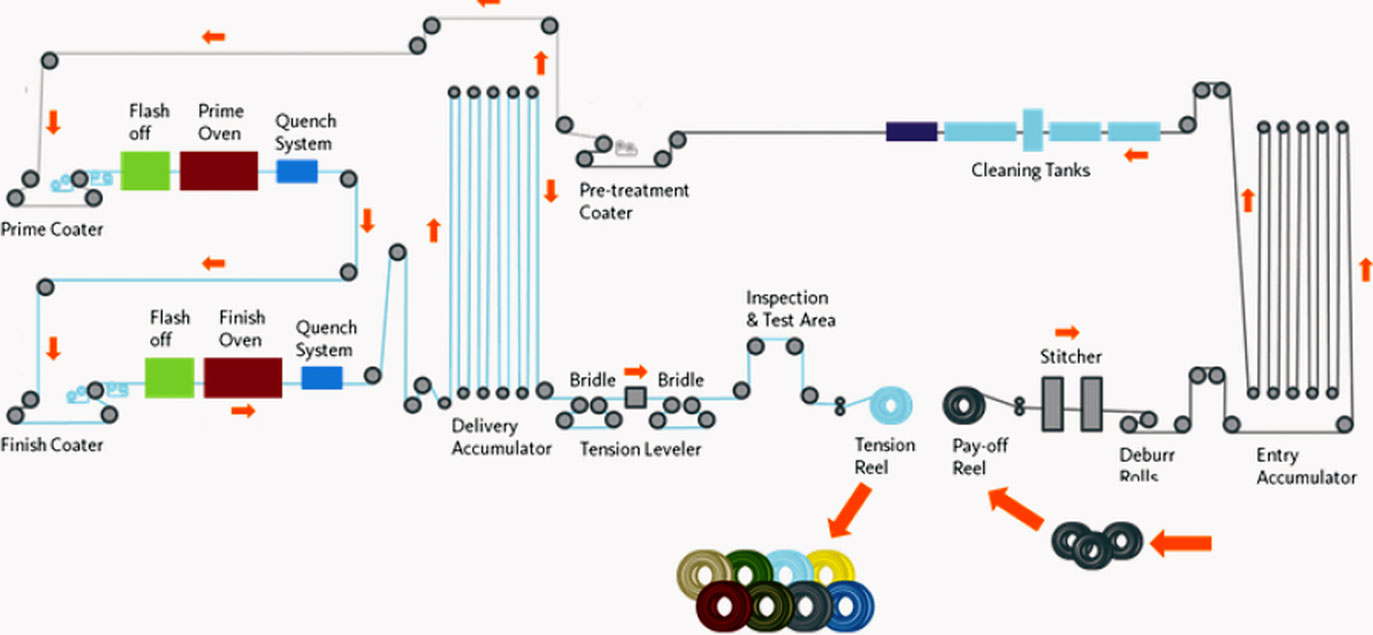

HERA member New Zealand Steel is the country’s sole producer of flat rolled steel products for the building, construction, manufacturing and agricultural industries. Their Paintline process produces pre-painted flat sheet steel.

The project focused on optimising operating conditions for the Paintline process by reducing transitional downtime between product runs. The target was to reduce transitional downtime between product insertions.

Using experimental data gathered from the NZ Steel facility, a numerical model was developed to simulate thermal conditions of the process. Theoretical functional specifications and production strategies were created from these simulations leading to the testing of the best strategies with live production conditions at NZ Steel.

From the trials, it was found that the downtime can be reduced as predicted in the modelling, leading to substantial economic benefits.