Client: New Zealand Transport Agency (NZTA)

Duration: Apr 2015 – May 2018

Location: Christchurch, New Zealand

Project value: NZD $112 million, value to JV $93 million

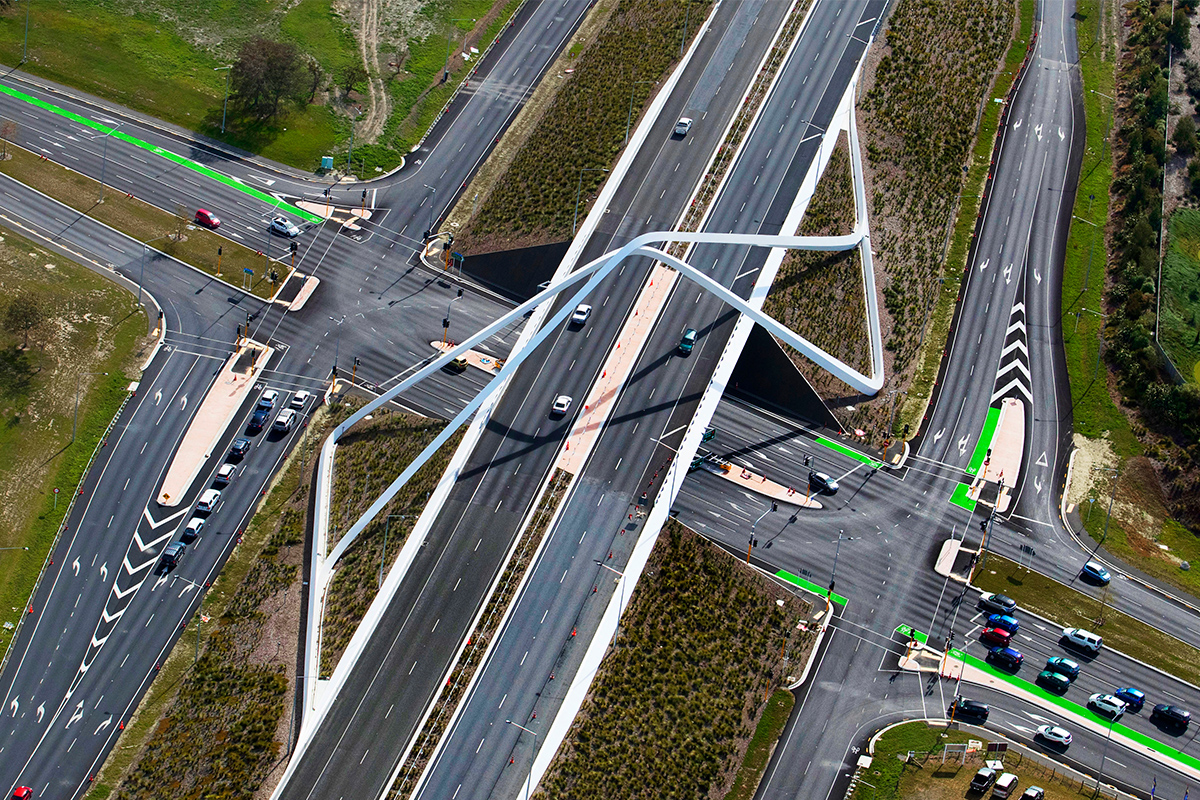

Working together, the project team delivered a new 4 lane highway and gateway bridge, including the iconic Memorial Gateway Arch, seven months ahead of schedule, to allow uninterrupted traffic flow for airport traffic. The JV project also delivered $3.3m of savings to NZTA through value engineering initiatives.

Located adjacent to Christchurch International Airport, the Russley Road SH1 upgrade is seen as the gateway to Christchurch.

The scope was comprised of a new 3.5km long, 4-lane highway, construction of two new grade separated interchanges, an increase in size of the existing Harewood Road roundabout and the addition of a newly built 150m pedestrian and cyclist underpass.

The cornerstone of the project is the Gateway Memorial Avenue flyover bridge with twin 400 tonne slender tapered arches sitting 27m above ground level.

The JV worked in partnership with NZTA under an ECI contract model to deliver the project.

Situation

The focus of the bridge was to provide a robust solution that satisfied the design requirements for strength, stability and durability without compromising the aesthetic of the arches. However, it became evident that it wasn’t feasible for the original designed arches to support the bridge without compromising its size and shape.

The arches also didn’t have the geometry of a pure arch. This provided buildability challenges which needed to be considered at the preliminary design stage to optimise its design. This took into consideration materials selection, and respective foundation requirements and construction risk.

Additionally, the project team had to manage concerns raised around reduced access to the Christchurch Airport. With an estimated 33,000 vehicles using Russley road daily and 20,000 using Memorial Avenue, it was an imperative that there were minimal delays to passengers during the closure of Avonhead Road and Wairakei Road changes.

A process further complicated by the Kaikōura earthquake which added substantial logistic challenges to delivery in terms of managing the complexities of design, procurement, and site activities.

Solution

The Project team worked closely with the Agency to re-evaluate the foundation requirements for the arch after NZTA’s decision to reduce the Importance Level of the Arch from 3 to 2. The removal of ground improvements and the value engineering created through this process delivered $1.8M in cost savings to NZTA.

The design has taken into account earthquake risk, structural and geotechnical design parameters through dynamic response spectrum analysis, lateral spread application, elastic buckling load analysis and comparison to British Standards to ensure that the reduction in section capacity would not compromise the safety of the bridge. The structure will also require minimal maintenance.

To overcome the design challenge of the arch supporting the bridge, a steel reinforced pier was incorporated mid-span into the bridge. This had a very tight tolerance of detailing and was achieved by using steel templates for setting the reinforcement foundation for the 3m deep pile caps and steel pier foundation plate of which some parts of the Y pier involved 80mm thick plate. The dual arches were also connected to provide additional lateral bracing.

This ensured the arch geometry was able to be maintained, while making the bridge structurally sound.

A number of materials were considered for the arch (including steel, aluminum and fibre reinforced plastic), however the option selected was steel plate sections fully continuous and integral at the foundations, with cased pile foundations.

Steel was selected as it affords extremely high onsite tolerances. Local trial fits and surveys were conducted for 18m segments in the workshop and on site to ensure quality and fit. The geometry of the arches was such it was not possible to achieve the required tolerances with concrete. The JV worked extensively with Eastbridge, the arch fabricators, to create an iconic but buildable solution.

The flexibility of the material also meant that the arches could be fabricated in 30 sections to deliver the constantly changing sizes of the design from a diamond shape at ground level to triangle at its crest.

To address traffic management concerns, the concept of a super roundabout was engineered during the ECI phase and developed during the construction phase.

At 500m long, it was the largest signalised temporary roundabout constructed in the Southern Hemisphere and provided a clear space for the development of the flyover while not compromising the safety of the road users during construction. It also avoided some 15 traffic management changes that were initially projected. The solution had been generated in the ECI phase but was further developed during construction. Key to the success of the roundabout was the extensive Stakeholder Engagement undertaken to ensure that road users knew what to expect.

Primavera P3 was also used to schedule the works to overcome the challenges posed by the Kaikoura earthquake. All of the arch sections were made in Napier and had to be transported by road, however Kaikoura earthquake forced the closure of SH1 for 12 months. McConnell Dowell had to develop an alternative approach to bring in each section to ensure timely and safe delivery.

After the removal of the Ground Improvements, the JV re-engineered the Contract Program with NZTA to provide a robust delivery plan.

Result

The finished highway and structures has achieved its purpose of reducing congestion, improving safety and travel times, and enhancing the visual impact of the western road corridor.

Delivered to budget, ahead of schedule, to a high-quality standard and safely, the Project demonstrates what can be achieved when the entire Team embraces “Best for Project“

If you’d like to find out more about this project, contact McConnell Dowell Contractors Representative Aidan Brannan by email at aidan.brannan@mcdgroup.com or by phone on +64 21 308 494.