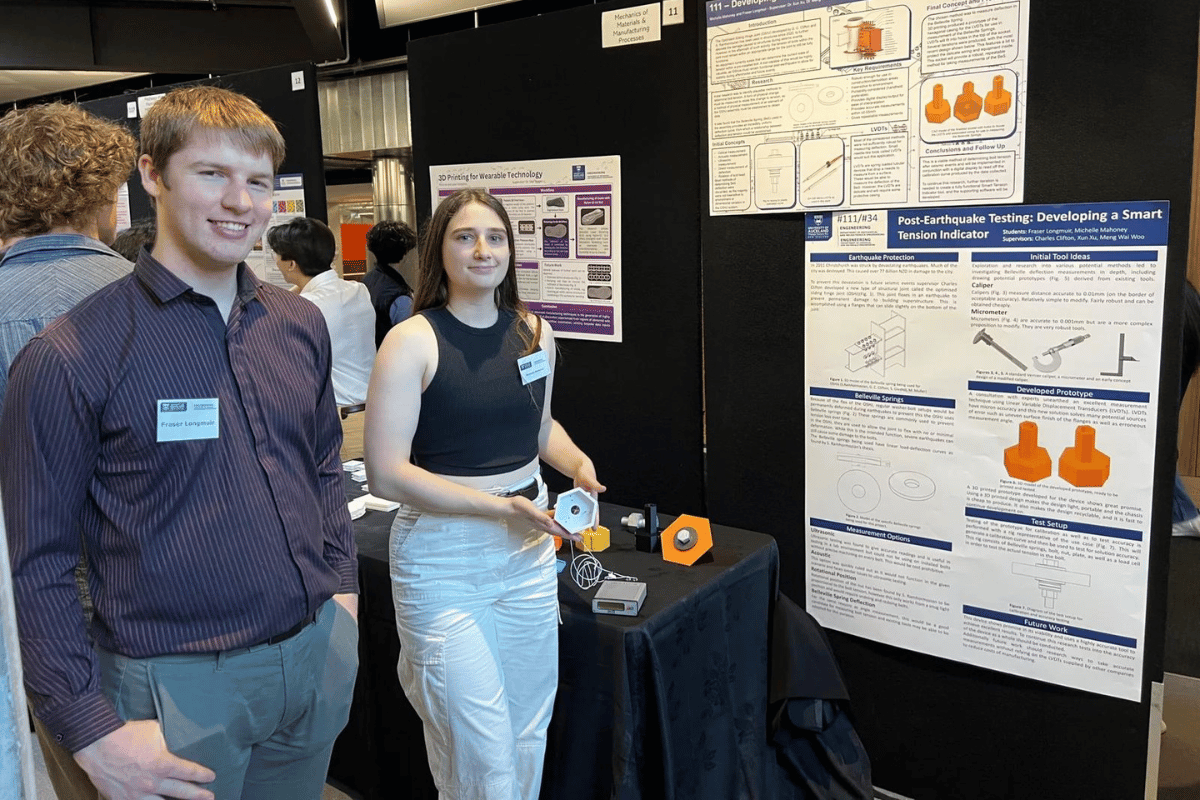

We recently had the pleasure of awarding Michelle Mahoney and Fraser Longmuir the HERA prize for the best final-year student project related to heavy engineering at the University of Auckland.

Their project, titled “Smart Tension Indicator,” was listed in the Industry 4.0 Smart Manufacturing Systems category and is addressing a challenge that is all too familiar to those putting up heavy steel frames that are at the core of many of our large buildings (of which many are in areas prone to strong winds and earthquakes).

The sections are pre-made by a steel fabricator in their workshop and are bolted together on-site using heavy-duty bolts.

The site crews must tighten these bolts to precise requirements to create secure and lasting connections. The task of the two students was to develop a system that could measure and record just how much each bolt was tightened.

The project is guided and inspired by Professors Xun Xu and Charles Clifton, both from the University of Auckland and is part of an event which brings various student projects together for review. The official flyer for the event saying: “The final year Research Project represents a significant point in an undergraduate Engineering student’s degree. These year-long research undertakings are the culmination of the knowledge the students have attained so far, applied to relevant situations that they have to test and prototype. Professor Gerard Rowe, Manukura Pūkaha / Dean of Engineering at the University of Auckland.”

Following the prize ceremony, we chatted with Fraser and Michelle about their experiences and challenges during their studies and their future plans.

How did you end up doing a project related to heavy engineering and what attracted you to the project?

Fraser: I was looking for a project that focused more on the material side of my studies and provided a challenge in areas I had yet to be exposed to much in my studies. Also, it was important for me to work with a team partner where I felt confident that we could focus on the technical challenges.

Michelle: I’ve been experimenting with engineering from a young age when my dad took me to his workshop and taught me the basics of welding and machining. I’d gained some experience in the industry and the proposed topic through my previous internships. I was looking for a project that allowed me to apply the theoretical knowledge I have acquired through my studies to a practical project.

What was the most rewarding part of the project?

Michelle: We experimented with several concepts before developing a methodology that allows us to achieve the desired measurements reliably. Moving past these issues and being able to build and validate a prototype within the timeframe of the project was quite rewarding.

Fraser: I was thrilled to see that the knowledge we have acquired in our studies has enabled us to go through the various phases of product design and answer the questions thrown at us along the way.

Now that you can see the end of your studies approaching rapidly, what are you looking for in your first job?

Fraser: I am happy that I have already secured my first job as a Process Engineer. What attracted me to the job was that it allowed me to apply the knowledge from my studies and that the company has a good company culture. I looked up company reviews online before applying for a position. It is also important that the company is actively addressing the sustainability challenges.

Michelle: I am currently considering continuing my studies for a little bit longer and adding a master’s degree. Overall, I’m striving for a job that challenges me and allows me to develop further. One key aspect I look at in a company is their attitude towards Health and Safety, which is a good indicator of a good company culture.

In your studies, you have heard about Industry 4.0 – the digital revolution refining manufacturing; what is your take on it?

This is what we both have been studying for – to further develop existing processes and products to make them better and more sustainable!

Industry 4.0 is providing us with the tools to achieve that. So, we say “bring it on!”.

Celebrating innovation with Industry 4.0!

Firstly, we’d like to offer a massive congratulations to both Michelle and Fraser for delivering an excellent project outcome and for very soon finishing their studies. We wish them both the best for their future in engineering and look forward to the positive contributions they will make to our industry.

If you are also interested in exploring the Industry 4.0 landscape further, a good starting point would be to assess your company’s Industry 4.0 readiness. The Smart Industry 4.0 Readiness Index is a valuable tool that can help organisations evaluate their Industry 4.0 readiness and develop a roadmap for their digital transformations.

A student project is an excellent way to involve the next generation of engineers in making that roadmap a reality.

If you want to develop your digital transformation roadmap, don’t hesitate to get in touch with our Senior Engineer – Advanced Manufacturing, Holger Heinzel via email: holger.heinzel@hera.org.nz or by mobile at: +64 21 164 1685.