We’re excited to bring to light a New Zealand case study on the use of 3D scanning as a new digital tool by one of our members.

Those of you at HERA’s Future Forum: 2020 VISION in February would have heard Des Watkins from Watkins Steel promote the use of digital technologies, including 3D scanning, as a new business model for steel fabricators.

Having a case study where Hawke’s Bay-based HERA member, Patton Engineering, has done just that is great for us as it allows us to demonstrate how our other members here in Aotearoa can do the same.

Seismic strengthening of Hawke’s Bay Hospital required a new approach

The Hawke’s Bay Regional Hospital Acute Assessment Unit required seismic strengthening to 70% NBS (IL3).

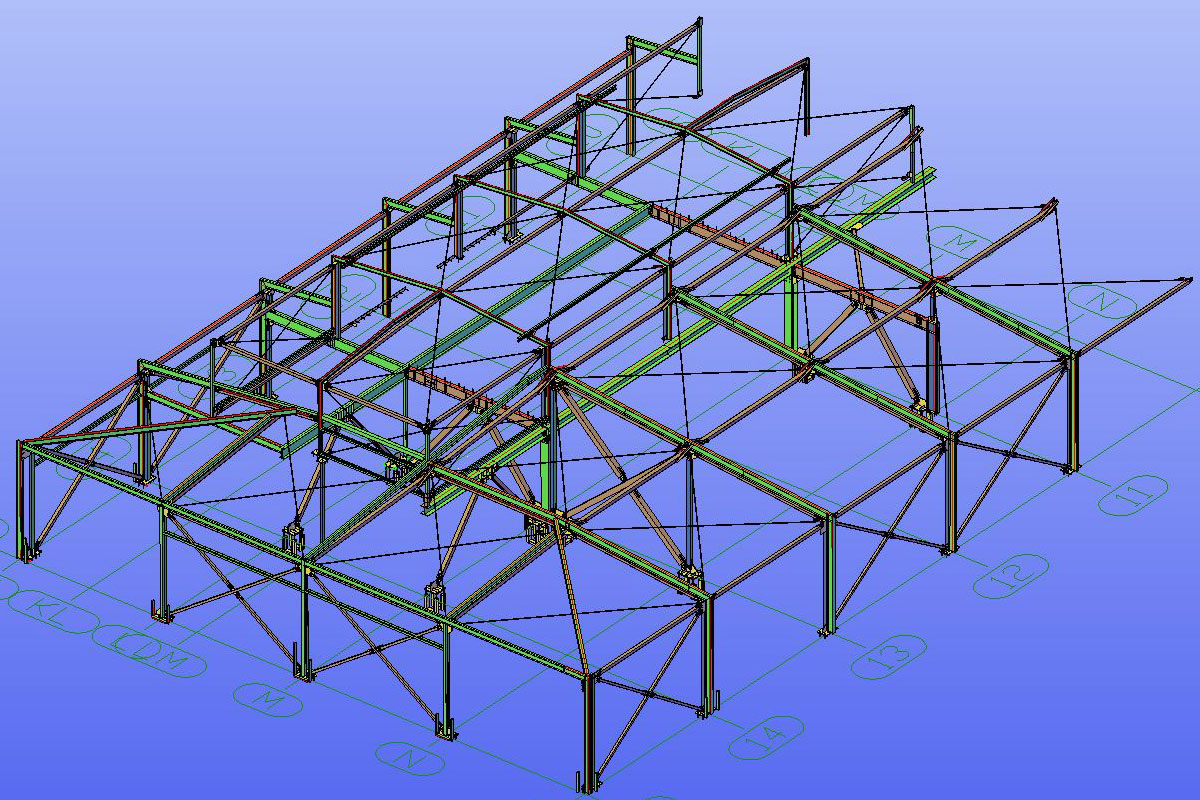

Patton Engineering, who is SFC CC3 & IIW ISO 3834.2 certified, was contracted to provide structural steel framing including structural steel modelling (BIM), steel fabrication, surface treatment and steel installation to the AAU (Acute Assessment Unit) first floor auditorium, library and plantroom.

For this half million dollar project, Patton Engineering implemented systems to ensure identification and full traceability complying with AS/NZS 5131.

To bring the structure up to the required seismic standard, the installation of structural steel bracing to the existing building had to be carried out.

Documentation of the “as built” environment required detailed site measuring, which was made difficult by existing mechanical services and access to hard- to-reach areas.

3D scanning’s accurate “as built” model offers alternative to traditional site measuring

To establish an accurate “as built” environment, Patton Engineering leveraged the use of the latest 3D scanning equipment and software.

Patton Engineering provided 3D scanning as an alternative to traditional site measuring to undertake digital documentation, accurately identifying and capturing site conditions, minimizing time spent on site and eliminating the need for multiple site visits to confirm details missed.

From these deliverables they were able to offer an accurate “as built” model of the existing space and identify out of plumb columns, deflection in the existing steel framing and possible clashes that the new steel would have with existing services and structural steel framing.

With +/- 1mm accuracy, site installation was achieved without design or fabrication issues.

3D scanning offers significant advantages: accuracy, time, detail

The accuracy of 3D scanning ensured design, fabrication and installation would provide a cost effective, time saving and innovative approach to the delivery of seismic strengthening to an essential government service.

3D scanning saved an estimated 60% of time spent on site in comparison with conventional manual measuring, with the ability to ensure the smallest details, which are often overlooked, were captured.

Capturing every detail in a single visit saved time on revisits to site, a cost that can escalate quickly if this process happens multiple times throughout the project.

Digital accuracy = time-savings and cost-savings

Mark Wharekawa, Engineering Programme Manager with Patton Engineering said: “Utilising 3D scanning technology to capture a detailed “as built” environment, was not only a valuable tool that aided in the accurate design, fabrication and installation of the structural steel work required to bring the existing structure to the required seismic specification, but it also allowed the structural steel package to be completed without rework or time delays due to design or fabrication errors.”

“Our work involving 3D scanning technology not only benefits our organisation in delivering an accurate service/product but we also offered to share and coordinate with other disciplines to ensure the successful delivery of the whole project”

If you would like further information about this project or Patton Engineering’s 3D scanning in practice, please contact Mark Wharekawa at mark@patton.co.nz

Des Watkins spoke at our Future Forum: 2020 VISION conference in February and you can find his podcast here and see how this pioneer made use of 3D scanning and other digital tools in his steel Fabrication business.

HERA has a range of support for our members to move to a more digital environment

We’re really proud to have developed out a strategy over the past year that is focused on future-proofing our industry for future sustainability. We want to support today’s industry, by innovating today.

As a result, we’ve in a strong position to help our members in the digital space, including:

- Putatara – our digital media studio and social media consulting service;

- Innovation Ready, Set and Go – our innovation program which will now be delivered digitally;

- Digital audits – where we now have capability to do during shut-downs if required;

- Software tools and design guides – which we are now developing to assist design engineers to design to NZS and AS/NZS standards.

These tools are all developed with the focus of positioning our industry strongly – and in the post-covid19 world, this has become more important than ever.

To find out more, please get in touch so I can ensure one of our team can assist you in taking advantage of these offerings.