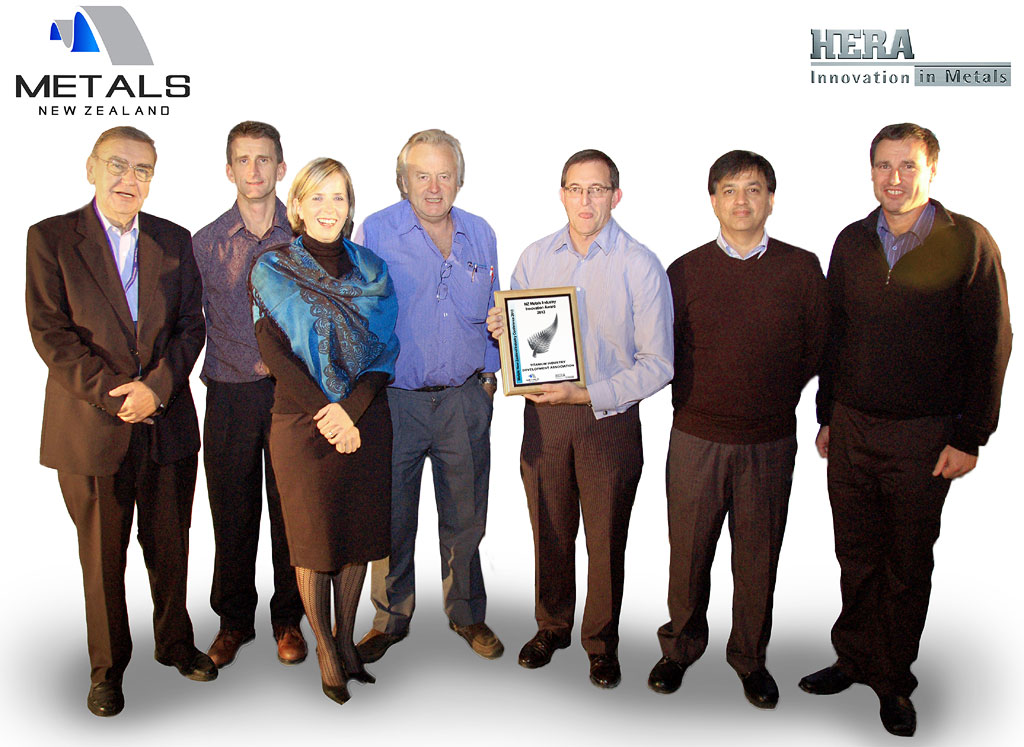

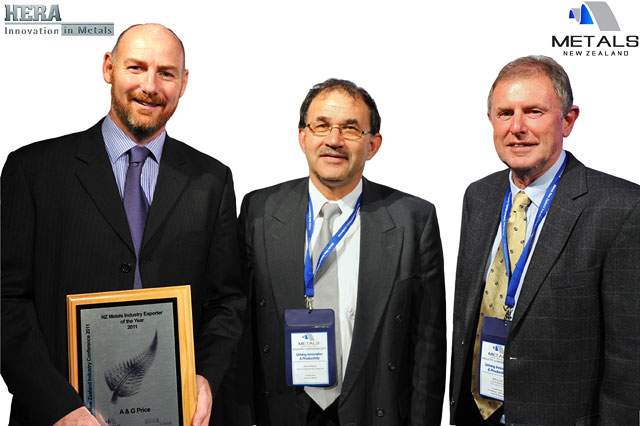

We hold our Industry Awards every two years to recognise members who’ve significantly contributed to our industry’s success.

This is part of our Nation Dinner which follows our Future Forum conference focused on building a tribe of metal heads and casting our eyes to the future so we can prepare for disruption.

What makes these awards so rewarding is that recipients are selected by their peers. An acknowledgement that we believe means so much more, because it comes from the heart of our industry – our members.

Please note that the 2023 Future Forum conference and Industry Awards Nation Dinner would traditionally have been held in 2022, but was postponed due to the impacts of Covid-19 and the restrictions that were in place at the time for large group gatherings.