A homegrown solution to steel decarbonisation is on the way in collaboration with industry.

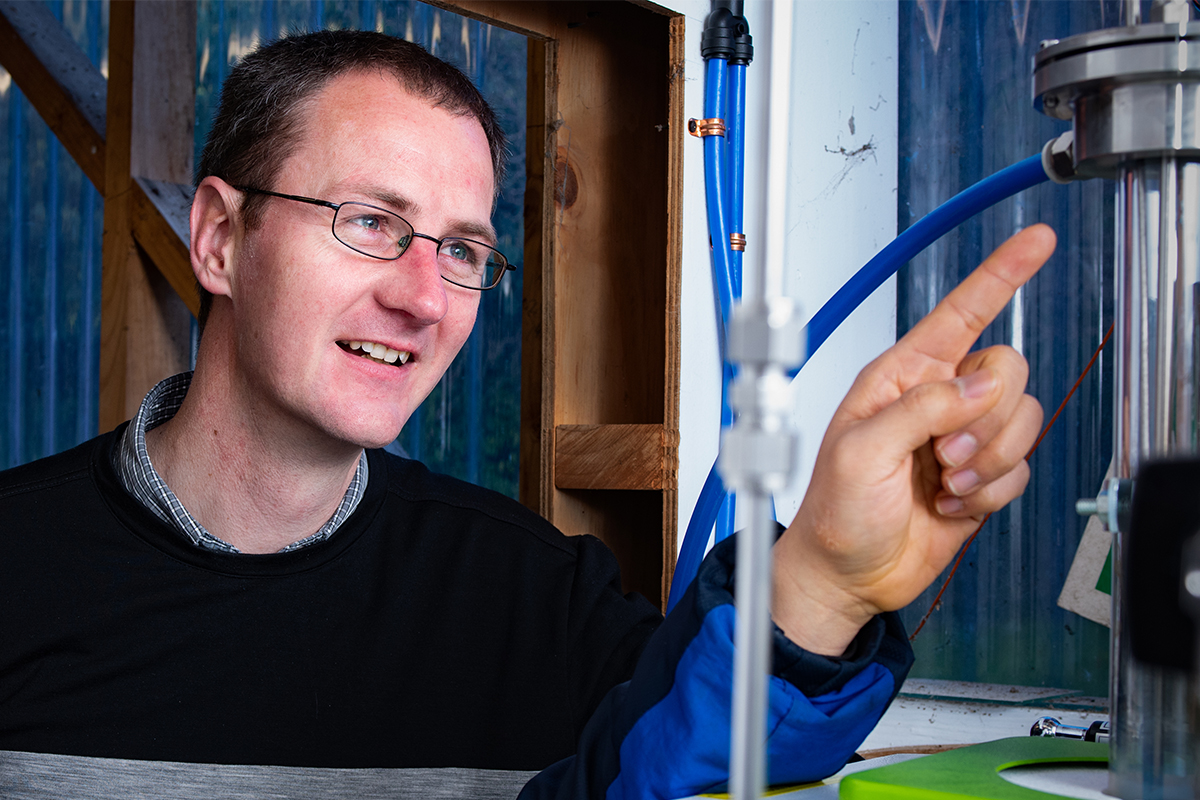

HERA has been tracking research being done by Dr Chris Bumby and team at the Robinson Research Institute for some time now. Their works first coming under our radar after they won our industry award for innovation in 2020.

At the time, they had developed a small-scale zero-carbon way to make iron that was specifically developed for New Zealand iron sands. The one-step process was looking promising in that it produced very high purity iron very quickly. They had also recently won a $6.5 million grant to start to scale-up the process to tens of kilograms level – taking it one step further towards the aimed eventual commercial scale.

We are now pleased to report that HERA member, New Zealand Steel, has announced funding to accelerate the development of a pilot-scale reactor for this process located at New Zealand Steel’s Glenbrook site.

This collaboration will explore how innovation in low or zero-emission technologies could be adopted to update a process which has largely remained the same since the Iron Age.

What are HERA’s thoughts?

Finding an alternative to coal as the reductant in the steel making process will be a game changer for the steel industry.

Currently, no commercially viable alternative exists for coal as the reductant in construction steel making globally. This limits the steel industry response to decarbonisation to carbon offsetting.

As a research association ourselves, HERA has always believed that research and innovation will (and does) play a critical role in accelerating the steel industry’s transition to a low carbon future.

As such, we’re excited to see New Zealand Steel involved in this project. This will solidify their parent company’s, Bluescope, commitment to reach a 12% steelmaking carbon intensity reduction target by 2030 and a net zero goal by 2050 across operations.

We have long asserted that steel will play a significant role in the low carbon transition, and this is one such way.

Want to know more?

Read the full press release here.