Steel structures performed exceptionally well during the February 22, 2011 Christchurch earthquake.

Such earthquake performance confirms that steel is the ultimate low-damage solution for modern multi-story buildings and structures. The performance also showed that the applicable New Zealand design and fabrication standards are safe – even though some minor damage in steel structures were reported (mainly due to overlooked shortcomings in detailing and execution).

Resilience based on robust research and testing

The resilience of steel structures has been the focus of long-term research and testing. This research has been done using experimental and in field quantifiable testing.

In the late 1990s, HERA commenced a six year research program to evaluate the performance of steel connections under earthquake loads in New Zealand. The program investigated both economic and technical aspects of connections to make them safer and cost-effective to design and construct.

The outcomes were incorporated into our Steel Connection Guide, NZS 3404, AS/NZSA 1554.1 and other relevant standards. It also added a degree of resilience to our steel design procedure required to sustain the seismic event without noticeable damage.

Immediately after the Christchurch earthquakes, we provided technical advice, training and R&D to support the rebuild. It was here that we recognised the risks resulting from structural steel procurement for the Christchurch re-build. This lead to us developing a Steel Fabricator Certification Scheme jointly with SCNZ. This certification program ensures that New Zealand fabricated steel structures comply with the highest level of quality.

A unique underlying standard that addresses the quality of structural steelwork, AS/NZS 5131, was also developed for the industry.

What is happening now in the seismic research space?

We continue to innovate in the field of seismic research exploring ways of improving productivity in steel construction. This involves understanding the manufacturing-related bottlenecks and applying advanced FEA-based design procedures to resolve them to simplify connection and weld details.

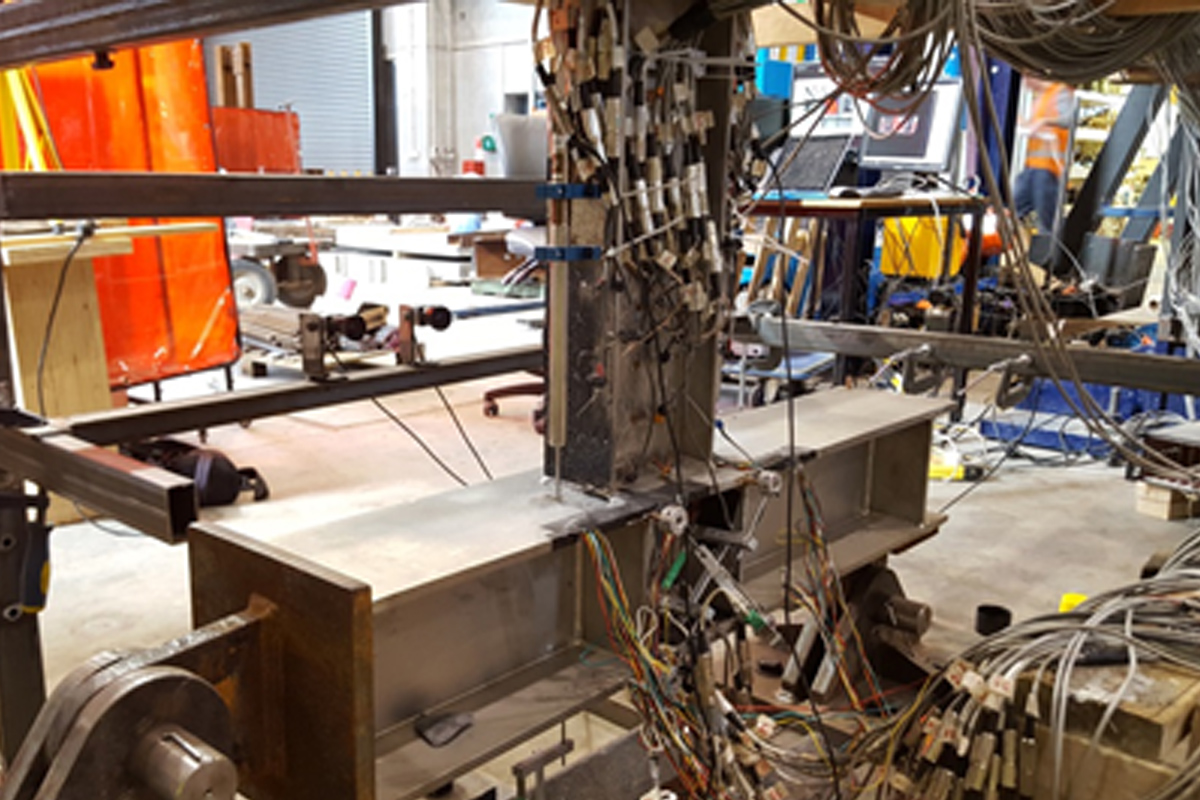

Our current research program is in collaboration with the University of Auckland, University of Canterbury, AUT and international partners. Most recently, we evaluated the seismic performance of welded beam-to-column connections using laser fused stainless steel structural sections and conventional carbon-manganese structural sections.

The main aim of this research was to understand the effect of using different material on seismic behaviour of welded connections. In addition, it investigated the feasibility of replacing more expensive weld details with more economical ones. The new weld details can be up to four times lower compared to the cost than butt weld and significantly cheaper than the cost of a large fillet weld.

We’re also focused on optimising the “demand critical” weld details used in primary seismic members such as eccentrically braced frames (EBFs), moment resisting frames (MRFs) and concentrically braced frames (CBFs). We have long-standing partnerships with Prof Charles Clifton and Prof. James Lim, University of Auckland, Prof. Gregory Macrae from University of Canterbury, and international experts Prof. Pingsha Dong from University of Michigan, USA, and Prof (Emeritus) Adolf Hobbacher, Germany.

A lot of this work has been done by PhD students financially supported by the HERA Foundation. This includes myself, having recently passed my final oral examination. Another, is PhD student, Mr. Xin Chen, who was recently granted a scholarship, and a number of other master students and PhDs who are working on or linked to this program.

So far, the key outcomes of these projects have been published in more than ten publications, and we have also recently published recommendations (HERA Report No R8-043:2021) for the use of “equivalent strength” effective full penetration of T-butt weld (EFPBW). This can be used by the fabricators subject to Design Engineers’ approval to replace butt welds by EFPBW subject to Factory Production Control (FPC) and design requirements of this report.

Our approach is that no research output is useful unless it is put into practice. That is why our HERA Report is supported by a robust industry training program for design engineers and fabricators.

The first two webinars will be held 8 and 10 September 2021.

References

- Taheri, H., Clifton, G. C., Dong, P. S., Karpenko, M., Raftery, G. M., & Lim, J. B. (2019). The Use of Effective Full Penetration of T-butt Welds in Welded Moment Connections. Welding in the World, 64(3), June 2020.

- Adolf F. Hobbacher, Michail Karpenko, Stephen J. Hicks, Patrick Schneider, Brian Uy: Establishing new brittle fracture provisions for the Australasian steel structures standards. Journal of Constructional Steel Research 155 (2019) 20–32.

- Adolf F. Hobbacher, Stephen J. Hicks, Michail Karpenko, Franz Thole and, Brian Uy: Transfer of Australasian bridge design to fatigue verification system of Eurocode 3. Journal of Constructional Steel Research, March 2016.

- Hafez Taheri, G. Charles Clifton, Pingsha Dong, Michail Karpenko, Gary M. Raftery, James B. P. Lim “Seismic test of the effective full penetration of T-butt welds in welded moment resisting connections”. 12th Canadian Conference on Earthquake Engineering (CCEE 2019). 17-20 June 2019.

- Hafez Taheri, G. Charles Clifton, Pingsha Dong, Michail Karpenko, Gary M. Raftery and James B.P. Lim: Seismic Tests of Welded Moment Resisting Connections Made of Laser-Welded Stainless Steel Sections. STESSA Conference 2018, Key Engineering Materials ISSN: 1662-9809.

- Michail Karpenko, Alan McClintock, Marlon Helmes and Holger Heinzel: Seismic Requirements for the Welding and Inspection of the K-Area in Hot Rolled Products to AS/NZS 3679.1. STESSA Conference 2018. Key Engineering Materials. ISSN: 1662-9809

- Alistair Fussell, Kevin Cowie and Michail Karpenko: Guide to the Use of International Standard Steels with NZS 3404 (Steel Structures Standard). Part 1: Structural Hollow Sections – EN 10219. HERA Report R4-154 and SCNZ Report 114:2020

- Alistair Fussell, Kevin Cowie, Michail Karpenko, Charles Clifton: Proposed Material Requirements for Category 3 Members in Seismic-Resisting Systems. SCNZ.org.nz, August 2020

- Adolf Hobbacher, Michail Karpenko. Provisions for avoiding brittle fracture in steels used in Australasia. International Institute of Welding IIW doc. X-1965r8-2020

- Taheri, H., Clifton, G. C., Dong, P. S., Karpenko, M., Raftery, G. M., & Lim, J. B. (2019). Performance of partial Penetration Welds in Seismic Moment Connections. Paper presented at SESOC Conference 2019- Challenging the Profession, 18-20 August 2019, SkyCity, Auckland

- Taheri, H., Clifton, G. C., Dong, P. S., Karpenko, M., Raftery, G. M., & Lim, J. B. (2019). The Use of Effective Full Penetration of T-butt Welds in Welded Moment Connections. International Institute of Welding (IIW) Document X-1955-19/XIII-2824-19/XV-1590-19.