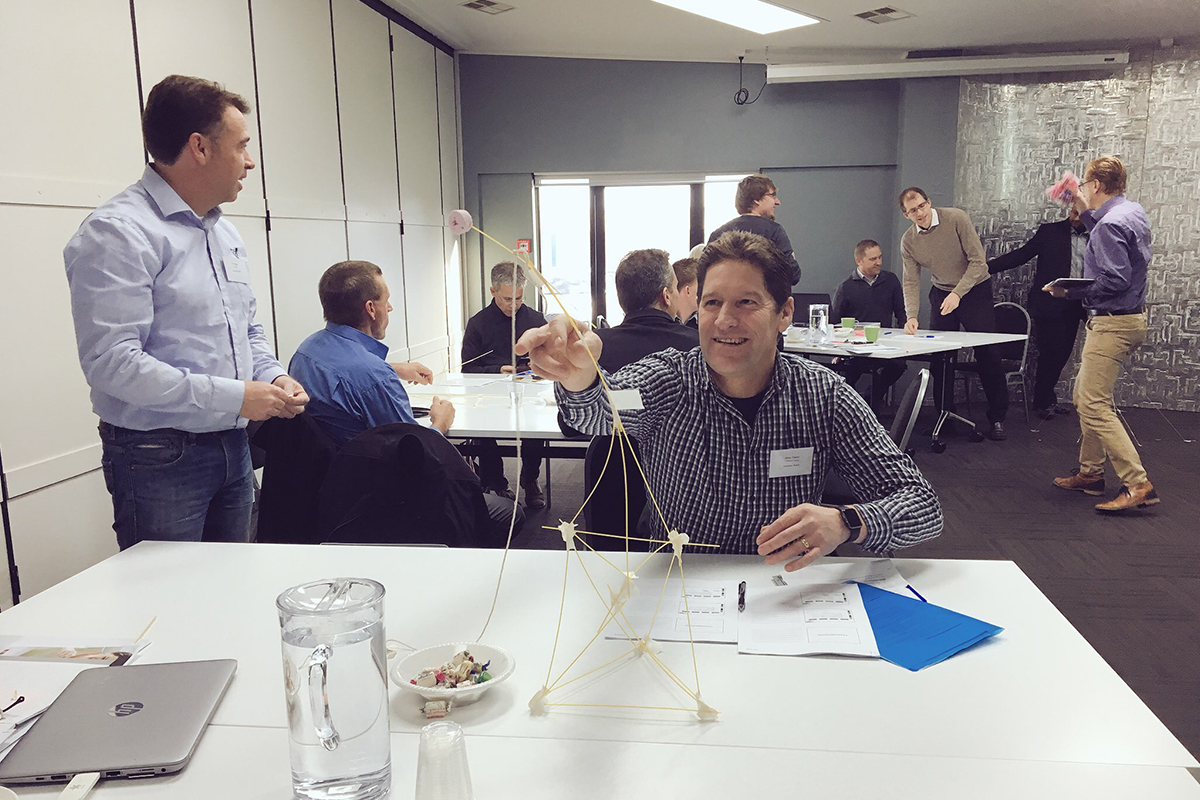

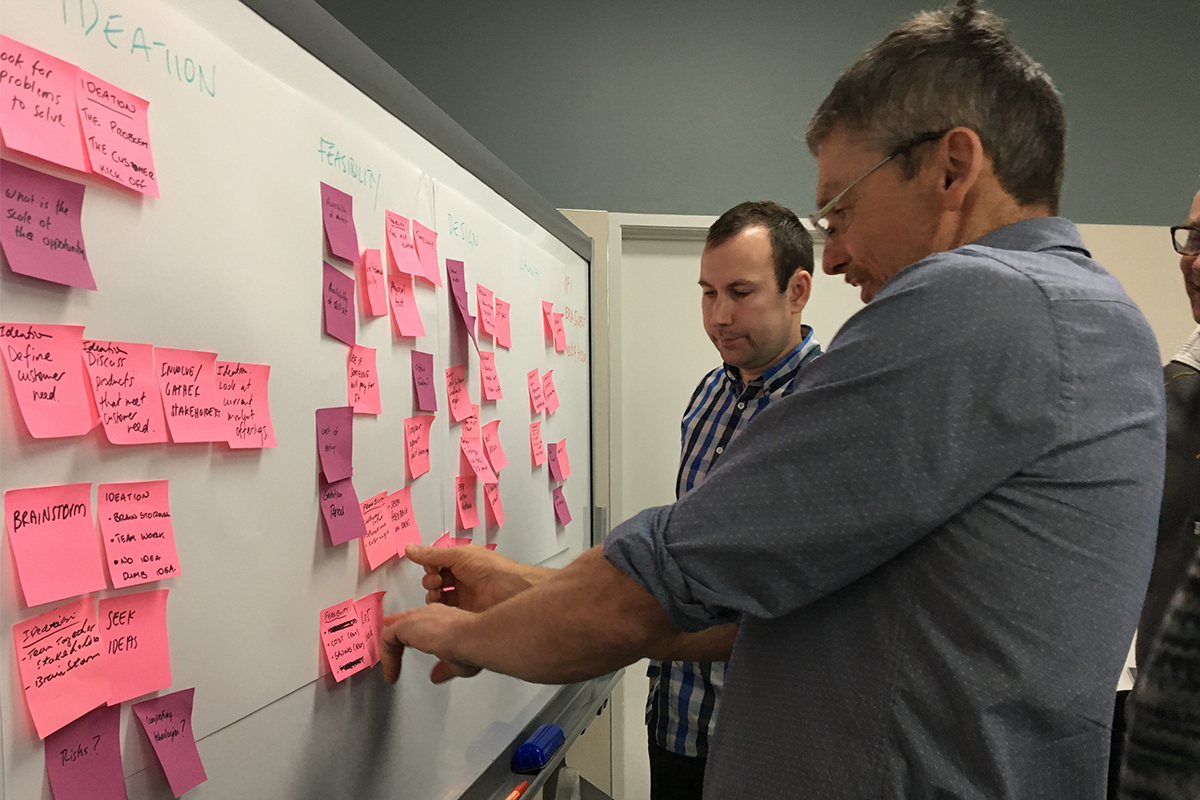

The end of July saw HERA deliver the second module of our Innovation READY program.

The aim – to mould the mindsets of those willing and open to re-assess how they’re currently doing business.

As an attendee, I have to be honest. The concept is quite hard to grasp. Like anything unexplored, it’s unknown. It challenges the boundaries we’ve set up in our world. It tells us that change is for the best. But why fix something that ain’t broke right?

It’s perhaps the very reason we avoid thinking about innovation and disruption in the first place!

I recently was in conversation with an engineer with a long history in our metals industry in New Zealand. He quite openly felt that HERA talking about ‘moving forward, innovation, positive change and being aware of disruption’ was trite.

It felt a little harsh. But on reflection – perhaps this is how many of you feel. But ask yourself – how else will you be challenged to contemplate these ignored concepts… if no one is consistently pushing you to?

We’ve been here before… so why haven’t we learnt?

As implied by Malcolm Frank, Paul Roehrig and Ben Pring in their book ‘What to do when machines do everything,‘ there’s plenty of evidence to show our economy is weakening. Wages are at a standstill, debt is rising, and productivity is weak. On top of that, major business trends are working against us. Increasing global competition, income inequality, erosion of privacy and security and emerging start-ups that are seeing legacy firms die. Last year’s A&G Price and Amtec closures a stark reminder of this. And, as we’ve seen in New Plymouth – political disruption in our Oil & Gas industry combined with new technology are taking our jobs!

It’s quite evident the old rules of work and business no longer apply. Yet loyally, much of our NZ metals industry are still trying to cling to them.

We’ve worried about ‘new machines and technology’ for a long time. Centuries in fact.

- The First Industrial Revolution saw the introduction of power looms. The Luddites in England responded by smashing the looms because they recognised it threatened their textile jobs. Quite rightly so – it did. But could you imagine a world today without this machinery? Where would the clothes on your back come from? And, how much would it cost you?

- The Second Industrial Revolution the steam engine enabled mechanisation. It was the age of steam and rail – but all that could be focused on was the impending widespread unemployment. Economist John Maynard Keys famously saying, “due to our discovery of means to economising the use of labour, we’re outrunning the pace at which we can find new uses for labour.” But fast forward to today – and the world didn’t end. This new technology didn’t stop our economy from functioning… it just changed the way it did.

- The Third Industrial Revolution of oil and assembly lines of mass production is where we currently sit. And it doesn’t take a rocket scientist to see that it is quite literally ‘running out of gas’. Whether we want to admit it or not, we’re on the cusp of entering:

- The Fourth Industrial Revolution. One that drips of a data driven age. Full of computers, automation, advanced materials and technology and artificial intelligence threatening to displace us. Looking back on history, you should now realise we’ve been here before. So why do we keep fearing change and instead defend staying the same? When will we acknowledge, embrace and proactively prepare for these changes instead?

I don’t know about you, but you’d have to kill me before I smashed up my iPhone like the Luddites did with the looms!

Has a computer put me out of a job? No.

Has it shortened my work day because I have less to do? No.

Has it changed the tasks I do in a workday? Absolutely!

They’ve made me more productive. I don’t have to spend hours doing mundane tasks, because an app or software can now do it for me more efficiently. It gives me more time to focus on the tasks that a computer can’t.

There will be blood

But let’s get real. My rosy outlook isn’t quite right either. People will lose jobs. And as Malcolm Frank and his colleagues state ‘there will be blood.’

They refer to Oxford University research which predicts 47% of US jobs could be automated away by 2025. This equates roughly to 75 million jobs. If we apply this across all industrialised nations we’re looking at around 173 million jobs gone in eight years! However, across the many studies done on this topic, the consensus is it won’t be that dramatic. More realistically ranging between 5 to 15% of jobs disappearing over the next 10 to 15 years.

This is still significant, 19 million for the US in fact. But in the age of the machine, history tells us we’ll also see the creation of jobs too. If we look at our journey since 2010 post the Great Recession, 15 million private sectors jobs were created in the US alone. This tells us although jobs will disappear, there will be more created than lost. So, what we should be asking ourselves is what is our succession plan for this displacement?

Saying you were too busy with day to day operations won’t cut the mustard when you find yourself out of a job.

How the heck do you innovate and pay the bills at the same time?

I’m not the only one attending the Innovation READY program – there are 17 others. And it seems to be the most commonly asked question.

With relief, this means I’m one of many on the innovation train for future sustainability seeking the answer. But on the flip side, it also points out how many aren’t thinking about their future enough to invest in it.

In today’s global market – successful businesses not only respond to their current customer or organisational needs. But also anticipate future trends to develop ideas, products, services or tools to meet future demand rapidly and effectively.

It’ll come down to one/some of our members being brave enough to give this innovation approach a go. Those that are willing to apply lean start up methodology to their operational processes, services, and product developments.

Let’s face it, we’re all looking for case studies, practical steps and tangible evidence before we take a punt. The truth is, the future won’t be run by those who created the new machines. But the ones who took the time (and risk) to figure out what to do with them in their business model before they became worth worrying about!

This boils down to leaders shifting their mindset away from just dollars in the bank right now. Instead, allocating and protecting a pool of resources solely focused on the future, while also running business as usual.

Our Innovation READY program can help achieve that. By equipping prospective innovation managers with the theory to prepare themselves and their businesses for implementing this innovation process.

The August session will focus on customer discovery – where to find your next innovation ideas and how to determine which ones will add value to your customers.

Manufacturing can lead this transition!

There’s no escaping the gravitational pull of the Fourth Industrial Revolution. So, deciding what you do about the new machine era will be the single biggest influence on what your future success looks like.

Automation has been the initial step in each industrial revolution. The Fourth Industrial Revolution will see the manufacturing sector become more intuitive, reliable and productive. And as the ‘what to do when machines take over the world’ book states:

“Much of this shift won’t be driven by companies that were started last year or even 10 years ago. But by companies started by our grandparents. Because they have access to the richest lodes of data. The ‘fuel’ for the new machine.”

News flash – that is a lot of our industry!

So, if you’re a business trying to make the best decisions for your operations, join the waitlist for our Innovation READY program by contacting our General Manager Industry Development Dr Boaz Habib.