Weld access holes are frequently required in the fabrication of structural components. The geometry of these structural details can affect the components’ performance.

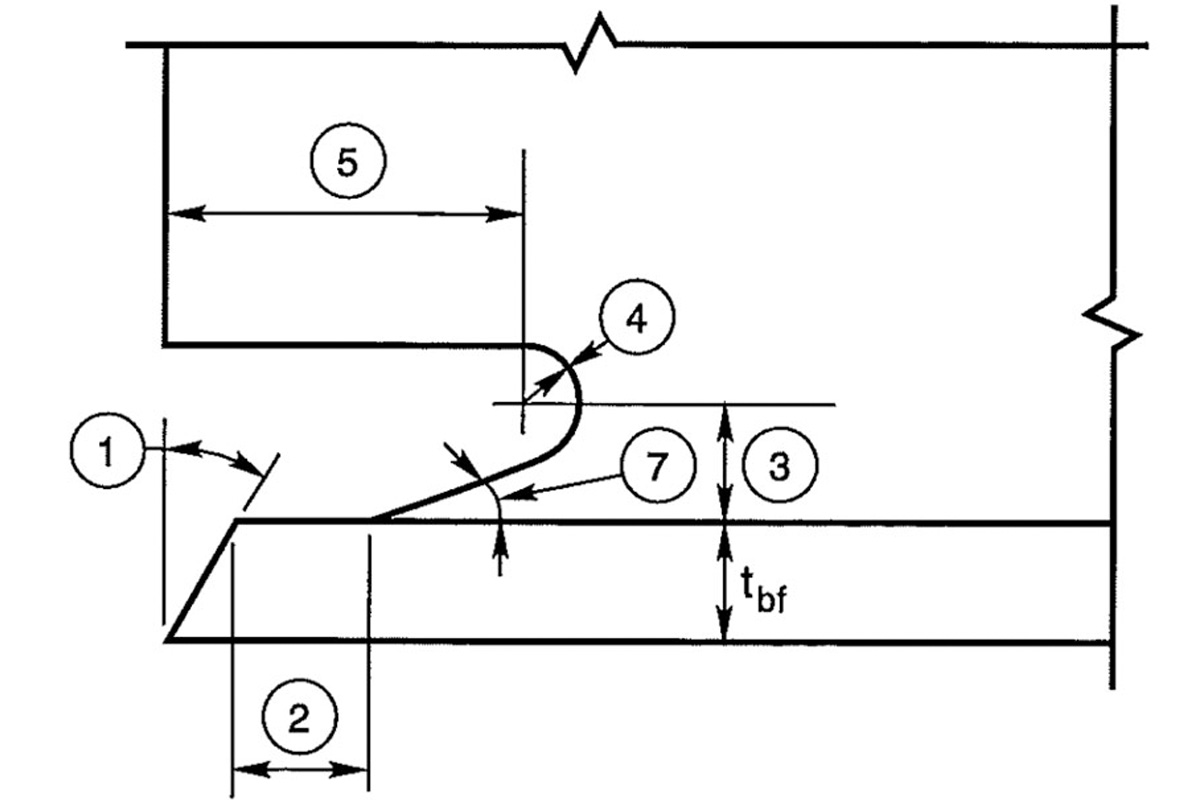

The size and shape of beam copes and weld access holes can have a significant effect on the ease of depositing sound weld metal, the ability to conduct non-destructive examinations, and the magnitude of the stresses at the geometric discontinuities produced by these details.

Research regarding the use of weld access holes has shown that the shape of the weld access hole can have a significant effect on the behaviour of moment connections.

The selection of weld access hole configuration should be evaluated on a joint-specific basis, based upon connection performance requirements. Some AISC’s Prequalified Connections for Seismic Applications do not permit weld access holes.

Cyclic testing has shown that use of weld access holes can cause premature fracture of the beam flange at extended end-plate moment connections. Therefore requirements for the weld access holes that include geometry and workmanship should be clearly specified. Corresponding guidance is given in Section 3.2.3.3 of NZS 3404.1:2009.

In general, the height of the access hole shall be not less than 1.5 times the thickness of the material, and not less than 25 mm not greater than 50 mm. The arc of the weld access hole shall have a radius greater than 10 mm.

Further information can be found in AWS D1.8 that specifies requirements for access holes for demand critical seismic welds. It is essential to closely follow recommendations of this standard where applicable as recommended access hole geometry(s) have been verified using extensive simulations and physical testing.

According to Section 9, ISO TR 17671-2 due to the risk of cracking, access holes should not be filled with weld metal unless required by the design specification.

Care should be exercised to avoid specifying special weld access hole geometries when not justified. Cutting out and subsequently filling access holes in (seismic) connections where no access holes have been specified initially may have a detrimental effect on the performance of the joint under high strain loading situation.

Therefore any decision as to whether to introduce/fill an access hole shall be approved by the Design Engineer. Recommendations on the selection of weld access hole on a joint-specific basis can be found in ANSI/AISC 358 Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications. Further recommendations can be found in AWS D1.8 Structural welding code seismic supplement.

For specialist advice, contact our General Manager Welding Centre Dr Michail Karpenko or Senior Welding Engineer Alan McClintock,

Update shared by our Senior Welding Engineer Alan McClintock